Our History

Innovation is our most important tradition

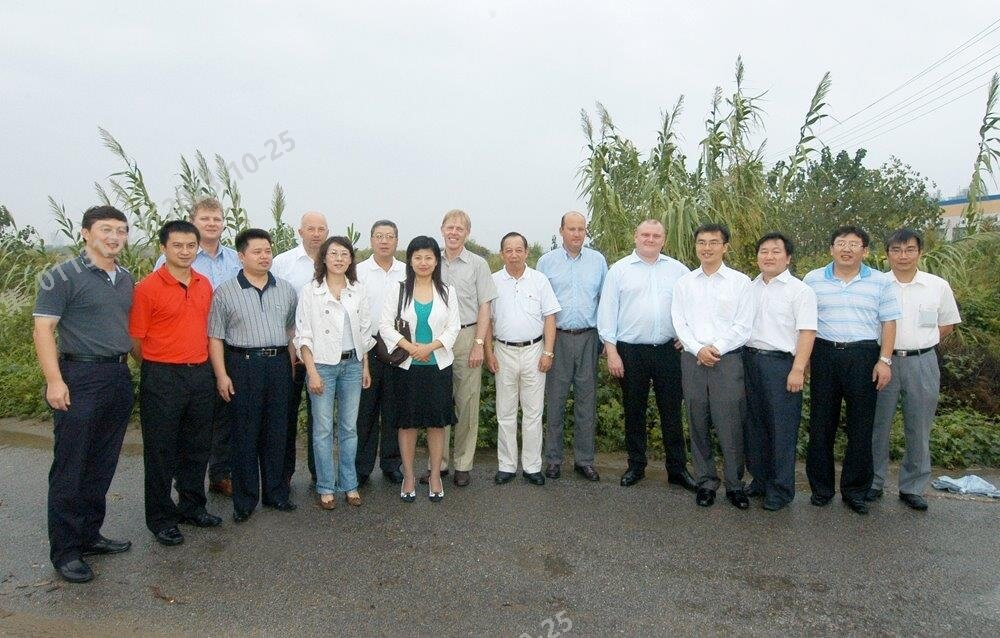

We are well positioned as a reliable and trusted liquid processing project delivery organization since 2007. With a team of experienced professionals and a deep understanding of the market, CLPT China quickly gained recognition for its reliability and dedication to customer satisfaction.